“We have been using Wheelabrator shot blast machine VH10/12 in our foundry since 2019.

For the parts availability and affordability, we started procuring shot blast consumables from the local suppliers. DISA India aftermarket team reached out to us with their local warehouse to offer parts available next to us.

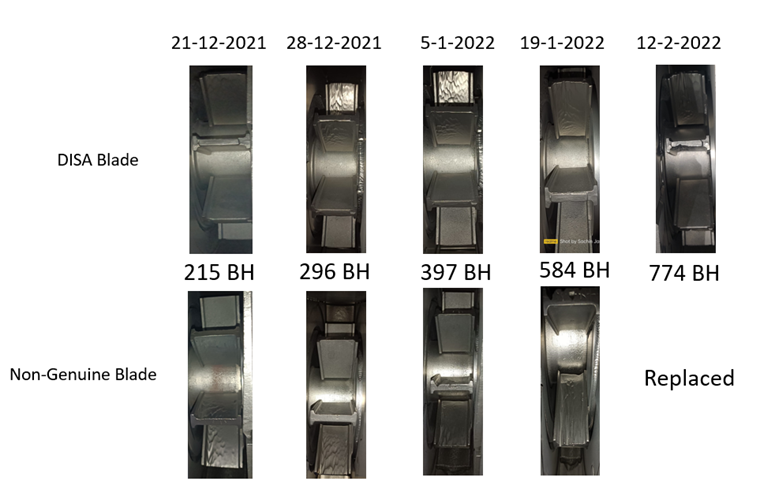

We checked wheel performance in comparison to another brand's wheel. Wheelabrator EZEFIT wheels outperforms another make wheel by more than 3 times in lifespan. We now decided to replace all other make wheels by Wheelabrator EZEFIT wheels in our shot blast machine.

We are seeing much improved machine performance and productivity.”

– Mr. Vishwas Khot, Manager Maintenance, Maurya Alloys.