“We installed Wheelabrator VP-18 Hanger-type shot blast machine in our foundry in 2013 together with the high-pressure moulding line with DISA MATCH 20/24 moulding machine.

We gave this machine on an O&M contract to a local service provider based on the tonnage basis with complete maintenance and parts under their scope. We saw that the machine performance was deteriorating drastically and asked DISA team to audit the machine and evaluate the reason. DISA India aftermarket team reached out to the contractor and audited the machine.

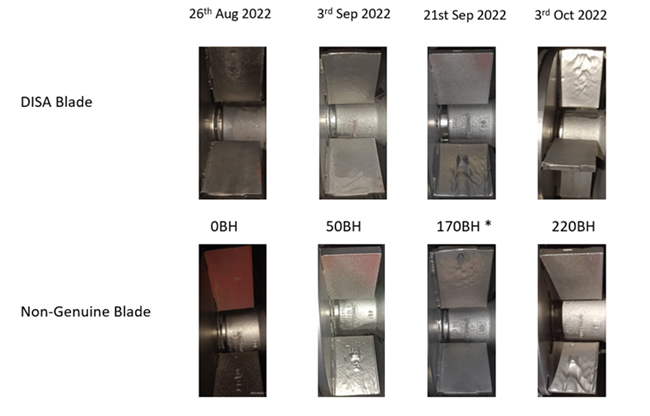

From August 2022 to October 2022, DISA was able to prove the cost benefit to the contractor through a trial on the machine. These visual proofs along with cost calculations made the contractor understand the importance of genuine parts and use them in our machine.”

– Mr. Nitin H Kondekar, Riddhi Casting, Manger Maintenance.